Hotline: +86-371-63232368 Email:service@van-research.cn

Industrial kiln

With the rapid growth of my country's industrialization, the demand for energy is increasing day by day, and the rapid economic development also leads to an imbalance in sustainable development. Saving resources and reducing energy consumption are the primary tasks of socialist construction at present. The energy consumption of industry is relatively large compared to other industries. From the perspective of the country and enterprises, if we want to take the road of sustainable development, we must use less resources to obtain large economic benefits, which will not only promote the development of enterprises, but also make Energy has been fully utilized, and it has also promoted the steady progress of my country's energy conservation and emission reduction cause.

Industrial kilns operate under heavy loads and alternately at slow speeds at high temperatures, and the maintenance of their accessories and the level of thermal system control are related to kiln operation and efficiency. Different types of kilns have the problem of high temperature insulation under normal working conditions. The loss of a large amount of heat results in a large amount of energy waste, which greatly shortens the life of the kiln. The long-term use of external components at high temperatures has great hidden dangers. . Therefore, in order to achieve the purpose of energy saving, industrial furnaces should first consider saving energy and make full use of it. The furnace body dissipates heat energy by heat conduction. In order to reduce the heat loss of the furnace body, an insulating layer is added inside the furnace body.

In recent years, a lot of in-depth research on refractory insulation materials has been carried out at home and abroad, and a variety of materials have been successfully developed, such as glass wool, mineral wool, microporous calcium silicate, composite silicate, closed-cell expanded perlite, ceramics Fiber, etc., to achieve high temperature resistance, low thermal conductivity, thermal shock resistance, flame retardant, and can slow down the industrial demand for heat loss caused by heat conduction, heat convection, etc. Most refractory insulation materials are loose and porous, and the voids in the material account for a large proportion. When they come into contact with moisture, they will absorb a lot of water. Since the thermal conductivity of water is much greater than that of air, it will seriously affect the thermal insulation performance of the material. Its own hydrophobicity is an important indicator for judging the performance of materials.

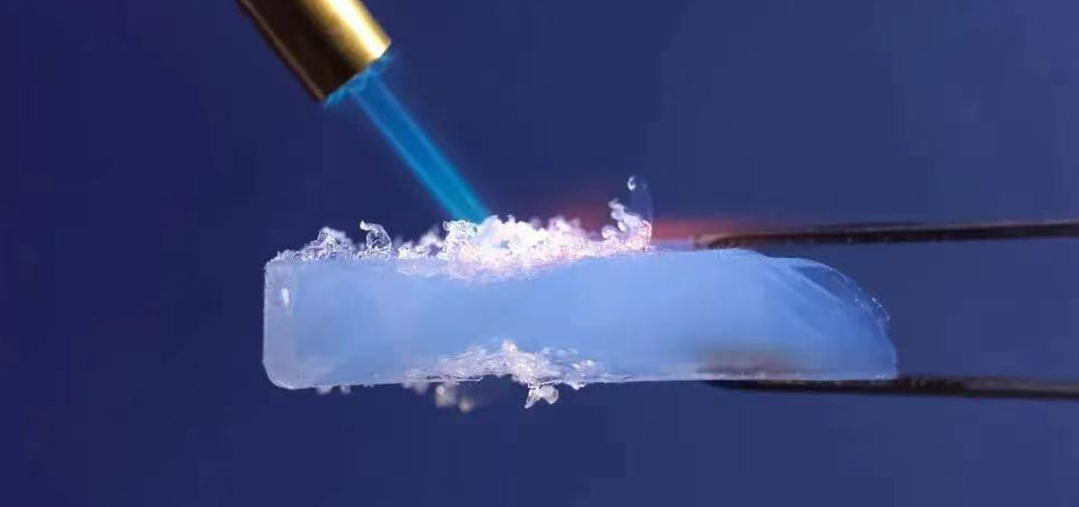

Aerogel thermal insulation material, Class A fireproof, temperature resistance up to 1800°C, high hydrophobicity (≥99%), with special treatment for infrared shielding and reflection, it is attached to the surface of the furnace body and has a strong isolation of infrared rays It can prevent the conduction and transmission of high-temperature thermal electromagnetic waves, effectively reduce the amount of heat absorbed by the object per unit time, and reduce the surface temperature of the object. By increasing the thickness of the aerogel material, the radiation energy level can be increased to the greatest extent, and the radiation degree of the heat energy can be increased when the heat energy is effectively stored, and the heat energy utilization rate can be improved in both directions, and the energy saving effect is better and obvious.

Advantages of aerogel insulation materials

High temperature resistance: thermal insulation and flame retardant, class A fire resistance, temperature resistance up to 1800 °C, thermal conductivity less than 0.03W/m.K, effectively avoiding various conduction heat and radiant heat, inhibiting the thermal radiation of high-temperature objects and low-temperature objects, and greatly reducing heat loss.

Strong infrared reflection effect: improve the heat exchange in the furnace, effectively store heat energy and increase the radiation of heat energy, reduce the temperature of the lining of the furnace, and improve the utilization rate of heat energy in both directions;

Space saving: reduce the thickness of the furnace wall without losing the thermal insulation effect, increase the volume of the furnace body under the condition that the appearance size remains unchanged, optimize the design of the thermal insulation layer of the furnace body, and save space and construction costs;

Good thermal shock resistance: tensile and compressive, dense material structure, high temperature and thermal shock resistance, no cracking or falling off, effectively reducing air convection heat dissipation;

Strong hydrophobicity: high hydrophobicity (≥99%), porous and loose, does not affect its performance after drying;

Green and environmental protection: inorganic water-based materials, no VOC (volatile organic compounds) are generated after high temperature heating, non-toxic and harmless, and environmentally friendly;

Sound absorption and noise reduction: Porous connected structure converts sound energy into heat for sound absorption, greatly reduces sound wave reflection and reduces industrial noise.

Hotline

Email:

Military-civilian Integration Industry Incubation Park,

Hupo Village, Zhanjie Town, Gongyi City, Henan Province

Copyright © Gongyi Van-Research Composites Co., Ltd. All Rights Reserved 豫ICP备2021033903号 SEO Powered by www.300.cn

Facebook

Facebook Skype

Skype Youtube

Youtube +86-0371-63232368

+86-0371-63232368